Rotary check valves

It is used in the installation of modern pipelines as a protective valve that excludes the reverse flow of the working medium, special check valves are used.

Types of valves

Rotary check valves are manufactured in 3 variants of connection to the pipeline:

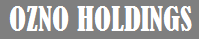

— Prefabricated inter-flange with mating flanges ( fig. 1 )

— Flanged (fig. 2 )

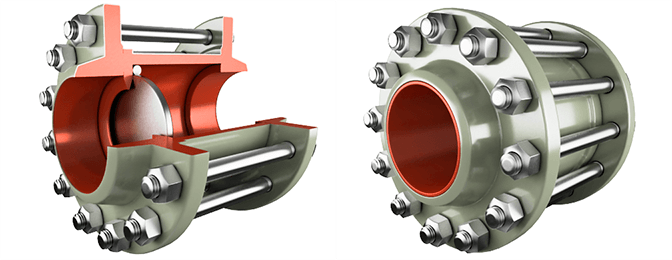

— Welded (fig. 3 )

All 3 options are fully ready for installation.

They are also distributed according to climatic conditions and environment: U1, CL, and UHL.