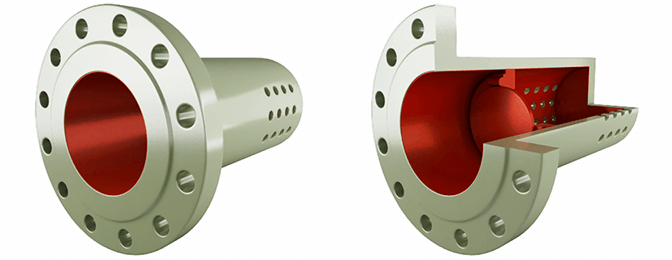

Intake valve

The check receiving valve is used for the intake of petroleum products through the intake pipeline and automatic prevention of backflow in pumping units at the ends of the suction medium pipelines.

Receiving type valves

The receiving valve is also necessary for holding oil products in these pipelines of underground and ground vertical tanks (industrial tanks) for storing oil (oil products).

KP intake valves can be made with a crown (for cleaning the bottom of tanks or industrial tanks of gas stations or oil depots and oil storage facilities), or with a intake (for pumping oil and petroleum products from tanks or industrial tanks of gas stations and oil depots).